Nothing is impossible

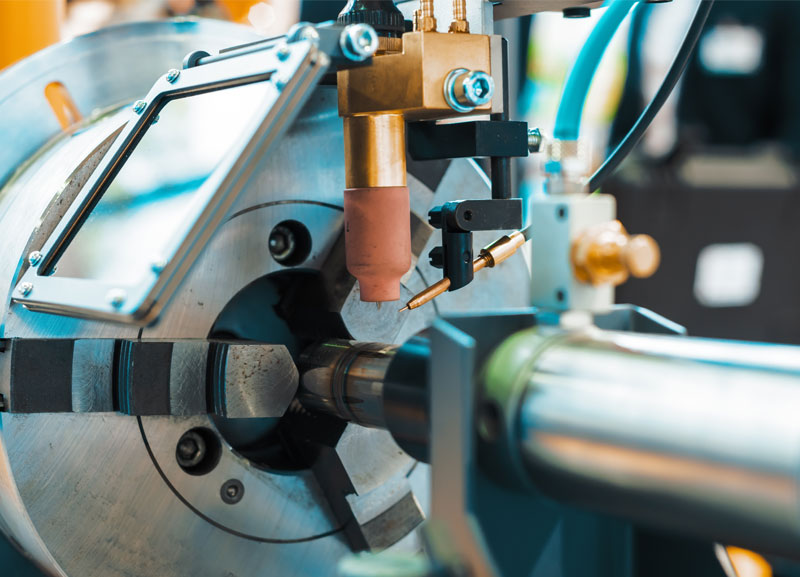

Years of experience in production - pressing, casting and turning - have made us an expert in these areas. Our own tool management enables high flexibility and minor downtimes. Due to a qualified supplier management we only cooperate with certified suppliers to guarantee high-quality products.

Machines Moulds and Tools Maintenance

- Specialized Engineer Operate Daily & Regular Inspection & Maintenance of Machines & Facilities, Moulds and Tools meanwhile recording;

- All Moulds, Tools, Fixture etc. Kept with Clear Identification make sure the correct Check In and Out.

- Localized Service and Technical Support for Both Machine and Moulds;

- Daily & Regularly Cleaning and Maintenance of Facilities and Working Facilities;

- Operation Instruction Listed on Site make sure the Operation Secure and machine & facility normal and stable operation

Production Scheduling and Planning

- Production Scheduled as per regular pre-planned and customized order;

- An order confirmation will be Processing Into the Production Schedule Stage;

- Rhinox Regularly Storage Raw Material Around 2 Month Consumption guarantee the Timely Delivery

- Normal Production Time Around 3 Weeks Dating from the Pre-Paid